The majority of solid waste falls into one of three categories. Because of this, there are three common applications of a solid waste treatment plant. Keep reading to learn more about these categories and the role that these treatment plants play.

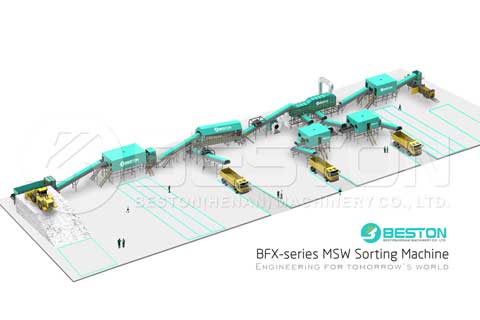

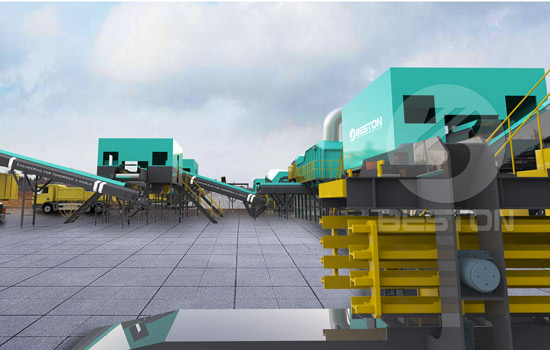

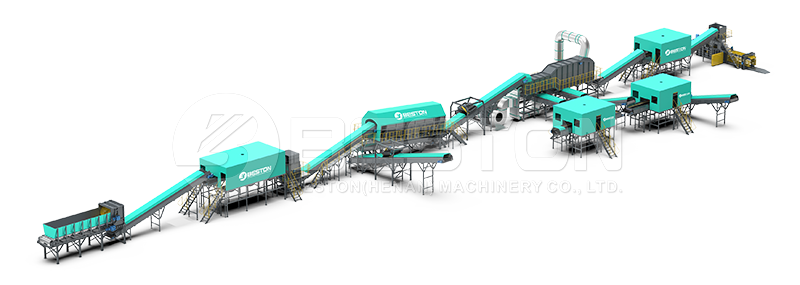

Municipal Solid Waste

These types of treatment plants are typically designed to handle the solid waste (residuos sólidos urbanos) that is produced by residential properties and office buildings. Many solid waste treatment plants fall into this category.

While these kinds of solid waste are often easier to deal with, there are some challenges associated with these types of plants. For example, finding an appropriate location for a treatment plan can be difficult. Transporting waste to a treatment plant can also be a challenge.

Hazardous Solid Waste

These types of plants deal with waste that has the potential to be highly hazardous. Because of this, a number of precautions must be taken at any facility that deals with this type of waste. If a mistake is made at a waste treatment plant like this, that mistake could have very severe consequences.

Since there are a lot of risks associated with these types of plants, a great deal of care goes into designing these plants. It is important to take precautions that help to reduce the risk of an accident occurring in the plant. Thankfully, the majority of plants today are very well designed.

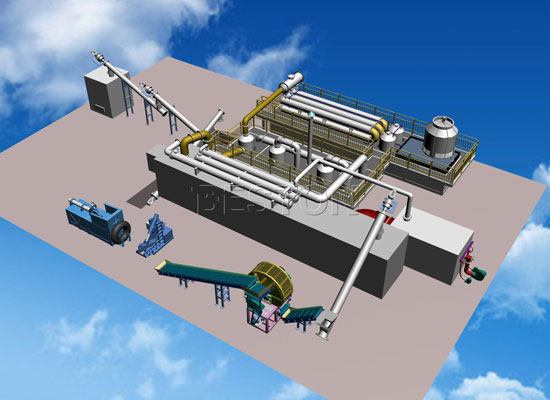

Industrial Solid Waste

Industrial facilities, such as warehouses or even construction sites, produce a great deal of waste. Many solid waste treatment plants are designed to deal with this type of waste(https://www.bestoneco.com/planta-pirolisis-neumaticos/). Because of the size and scale of these sites, plants often have to deal with large amounts of waste.

Although there are unique challenges associated with industrial solid waste, these plants are specifically designed to address these challenges. These plants work to ensure that waste can be treated safely and efficiently. Because there are many different types of industrial facilities, you’ll also find a wide range of industrial solid waste treatment plants.

Other Categories

While these are three of the most common applications of solid waste treatment plants (tratamiento de desechos), these plants do have other applications as well. For example, there are plants that are designed to process and deal with agricultural waste and plants that treat biomedical waste. There are even waste minimization plants.

There is a great deal of solid waste produced across many different industries, and it is essential that that waste is always able to be disposed of. It can be beneficial to learn more about all these types of waste treatment plants and how they typically function. Understanding these plants can give you insight.

These are the three most common applications of a solid waste treatment plant. Most of the plants you’ll see are designed to manage one of these types of waste. With that said, there are also plants that can handle more than one type of waste. It’s best to learn more about these plants, particularly if you’re going to be investing in a waste treatment plant (recicladora de basura).