The operational stability of a charcoal making machine is crucial for long-term projects in the biomass energy industry. As the demand for sustainable energy solutions grows, businesses are increasingly relying on biochar and charcoal production to meet environmental goals. However, ensuring that these machines operate efficiently over extended periods requires careful consideration of design, maintenance, and adaptability to various raw materials.

Design Considerations for Stability

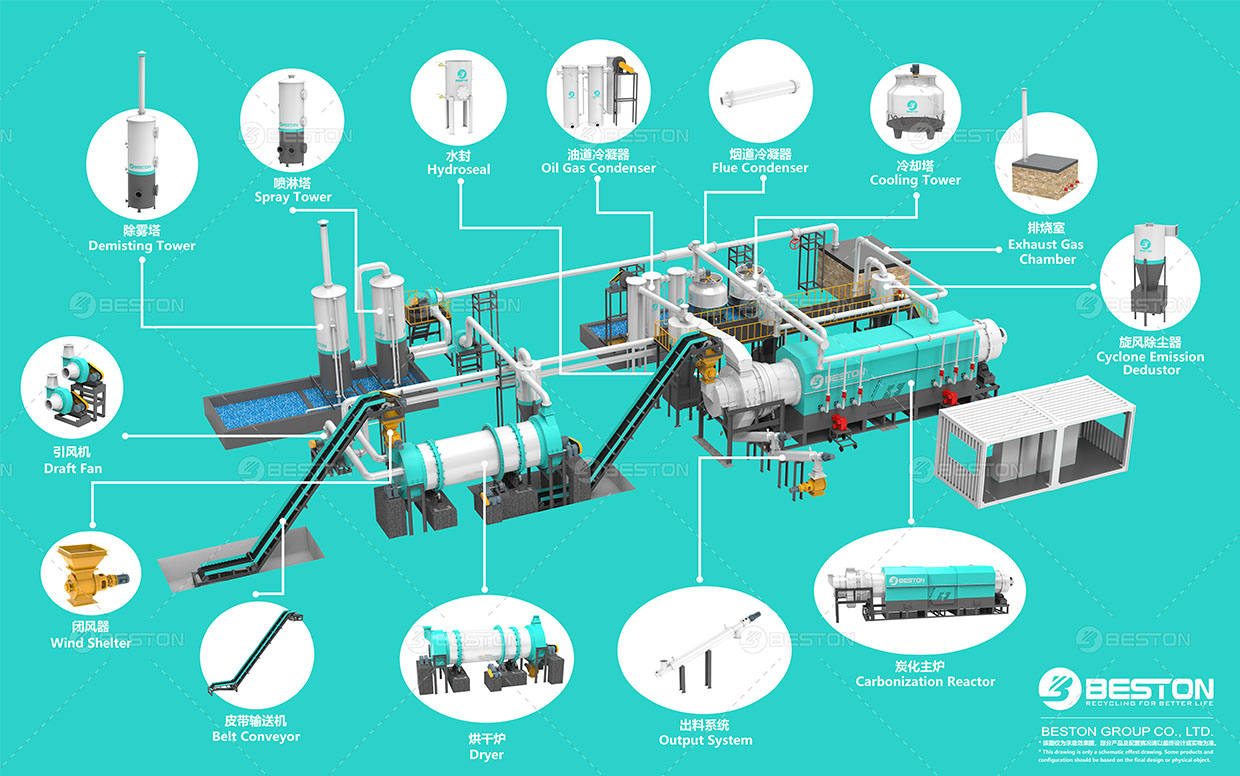

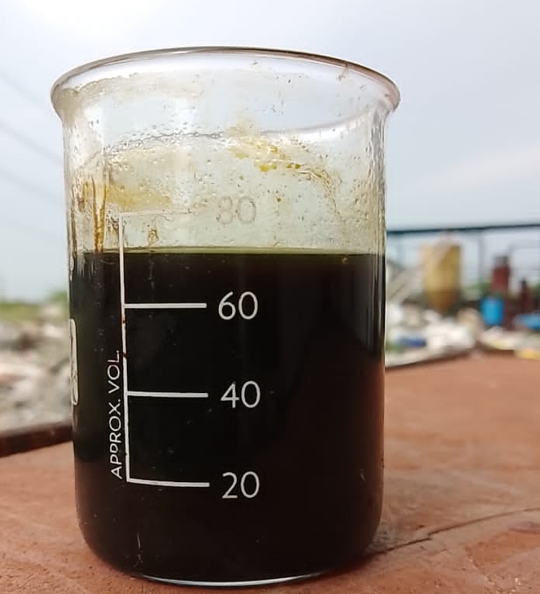

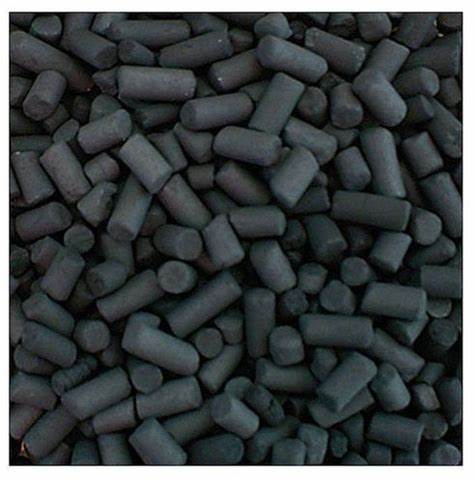

One of the primary factors in ensuring the operational stability of a charcoal making machine is its design. Machines equipped with a high-quality biochar reactor for sale are generally more robust and capable of handling the stresses of continuous operation. The biochar reactor plays a pivotal role in the pyrolysis process, where organic materials are heated in the absence of oxygen to produce biochar. A well-engineered reactor can reduce wear and tear, improve energy efficiency, and enhance the overall lifespan of the equipment.

Additionally, the material of construction and heat-resistant components used in the design significantly impact machine performance. Stainless steel, for example, is commonly chosen for its corrosion resistance and durability under high temperatures. The ability to handle varying moisture levels in biomass, such as rice husks, further adds to the operational reliability of the machine. The rice hull carbonizer, for instance, is designed to efficiently convert rice husks into charcoal while maintaining consistent operational efficiency.

Maintenance for Longevity

The stability of a charcoal making machine in long-term use is also heavily influenced by the maintenance practices employed. Regular inspections, cleaning, and lubrication can prevent the buildup of carbon deposits that could hinder machine efficiency. Scheduled maintenance ensures that parts such as the conveyor, drum, and biochar reactor remain in optimal condition. For businesses operating large-scale biochar plants, investing in a robust preventive maintenance program can significantly reduce downtime and costly repairs.

In addition to scheduled checks, operators should be trained to identify early signs of wear, such as excessive noise, temperature fluctuations, or unusual output characteristics. These proactive measures allow businesses to address issues before they result in significant malfunctions or system failures, ensuring that the machine runs efficiently for the long term.

Adaptability to Raw Materials

A charcoal making machine’s ability to adapt to different raw materials is essential for operational stability. The feedstock used, whether wood, agricultural waste, or rice hulls, can vary in moisture content and density. The machine must be capable of handling these fluctuations without compromising its performance. The rice hull carbonizer, for instance, is specially designed to process rice husks, a commonly available agricultural waste material in regions like Ghana. However, the system’s ability to switch between different types of biomass without requiring extensive modifications is a key attribute for operational stability.

Flexibility in feedstock processing allows companies to maintain consistent output, even when raw material supply fluctuates. This versatility also ensures that the biochar plant can continuously meet production targets, regardless of seasonal changes or supply chain disruptions.

The Role of Automation in Long-Term Stability

Automation technology plays an important role in improving the operational stability of charcoal making machines. Advanced control systems enable operators to monitor and adjust various parameters such as temperature, pressure, and material feed rates in real time. This reduces the risk of human error and enhances machine efficiency. For example, automated systems in a biochar plant can adjust the heat input based on the moisture content of the biomass, ensuring optimal conversion rates and reducing the risk of damage to the machinery.

Furthermore, automation helps optimize energy usage, which is critical for reducing operational costs. With the increasing demand for charcoal and biochar, machines like the charcoal making machine in Ghana are becoming increasingly automated, offering greater precision in the pyrolysis process.

Conclusion

The operational stability of a charcoal making machine is essential for the success of long-term projects in the biochar and charcoal production industries. By focusing on robust design, proactive maintenance, adaptability to raw materials, and leveraging automation, businesses can ensure the sustained performance of their equipment. As the industry grows, the continuous development of more efficient and durable charcoal making machines will contribute to the advancement of sustainable energy solutions worldwide.