Choosing the right charcoal making machine manufacturer is a crucial step in ensuring the success of your charcoal production business. With a plethora of options available in the market, it can be challenging to navigate through the various features, specifications, and claims made by different manufacturers. In this comprehensive guide, we will walk you through the key factors to consider when choosing a manufacturer of charcoal making equipment. By the end of this post, you’ll be equipped with the knowledge needed to make an informed decision that aligns with your production needs and business goals.

Understanding Your Requirements

Before diving into the details of different charcoal making machines and manufacturers, it’s essential to have a clear understanding of your specific requirements. Consider factors such as:

Production Capacity

Determine the amount of charcoal you plan to produce on a regular basis. Manufacturers offer machines with varying capacities, so knowing your production volume is crucial in selecting the right-sized equipment.

Raw Materials

Different machines are designed to handle specific raw materials, such as wood chips, sawdust, rice husks, or coconut shells. Identify the primary raw material you’ll be using and ensure that the machine you choose can process it efficiently. And make them a suitable size to feed into the biochar pyrolysis reactor.

End Product Specifications

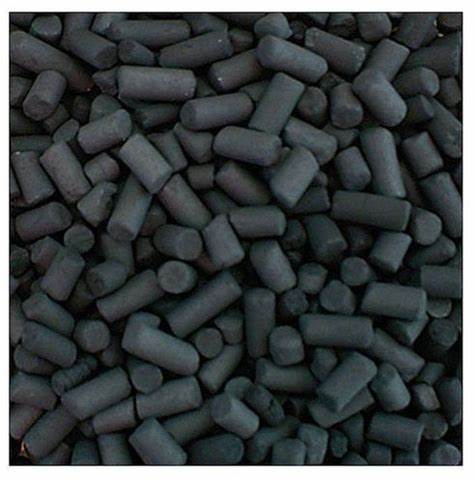

Define the characteristics of the charcoal you intend to produce, such as size, shape, and quality. This information will help you choose a machine that meets your desired output specifications.

Researching Charcoal Making Machines

With your requirements in mind, it’s time to start researching the available charcoal making machines and manufacturers. Consider the following factors during your research:

Machine Types

There are various types of charcoal making machines, including:

Carbonization Furnaces: Traditional method involving heating biomass in a sealed container.

Continuous Carbonization Machines: Continuous and automated processes for large-scale production.

Rotary Drum Carbonization Machines: Uses a rotating drum for efficient carbonization.

Understand the pros and cons of each type to determine which one suits your production needs.

Manufacturer Reputation

Look for manufacturers with a solid reputation in the industry. Read customer reviews, testimonials, and case studies to gauge the satisfaction of other businesses that have used their machines.

Quality of Materials

Examine the materials used in constructing the machine. It should be durable and resistant to the harsh conditions of carbonization. Stainless steel is a common choice for its corrosion resistance.

Energy Efficiency

Consider the energy efficiency of the machine. An energy-efficient charcoal making machine can significantly reduce operational costs over time.

Automation and Control System

Modern charcoal making machines often come with advanced automation and control systems. Evaluate the ease of operation, monitoring capabilities, and the level of automation provided by the manufacturer.

Maintenance Requirements

Check the maintenance requirements of the machine. A reliable manufacturer will provide clear instructions and support for routine maintenance tasks.

Certification and Compliance

Ensure that the manufacturer complies with relevant industry standards and certifications. This is crucial for both the quality of the machine and environmental sustainability.

Comparing Manufacturer Quotes

After narrowing down your options based on the research, it’s time to reach out to manufacturers for quotes. During this phase:

Cost Analysis

While cost is a significant factor, it shouldn’t be the sole determinant. Consider the overall value offered, including biomass pyrolysis machine quality, features, warranty, and after-sales support.

Warranty and Support

Check the warranty offered by the manufacturer. A longer warranty period indicates the manufacturer’s confidence in the durability of their machine. Inquire about the availability of technical support and spare parts.

Customization Options

Some manufacturers offer customization options to tailor the machine to your specific needs. Inquire about the flexibility of customization and any associated costs.

Delivery Time

Consider the delivery time for the machine. If you have strict timelines for starting your charcoal production, choose a manufacturer with a track record of timely deliveries.

Payment Terms

Clarify the payment terms and conditions. Be wary of manufacturers requiring a large upfront payment. A reasonable payment schedule ensures a fair deal for both parties.

Making the Final Decision

After collecting quotes and additional information, it’s time to make the final decision. Consider the following steps:

Reference Check

Contact references provided by the manufacturer. This could include businesses that have previously purchased the same machine model. Ask about their experiences and any challenges faced.

Visit Manufacturing Facilities

If possible, visit the manufacturing facilities of the shortlisted manufacturers. This provides insights into their production processes, quality control measures, and overall commitment to excellence.

Final Negotiation

Negotiate the final terms, including price, delivery, and any additional requirements. Be open to a constructive dialogue to ensure a mutually beneficial agreement.

Finalize Contract

Carefully review the contract terms and conditions before finalizing the agreement. Ensure that all agreed-upon details are documented in the contract to avoid any misunderstandings in the future.

Ongoing Relationship

Building a strong relationship with your chosen manufacturer is key to long-term success. Communicate openly, provide feedback, and stay informed about any updates or improvements in their technology.

Conclusion

Choosing the right charcoal making machine manufacturer is a critical decision that requires careful consideration of various factors. By thoroughly understanding your requirements, researching available options, and comparing quotes, you can make an informed choice that aligns with your business goals. Remember that the success of your charcoal production venture depends not only on the quality of the machine but also on the ongoing support and partnership with the manufacturer. View a recommended manufacturer noe: Beston Group Co., Ltd..