Are you thinking of a business idea where you can meet your customers’ demands throughout the year? First, you need to think of something that has a consistent demand for twelve months. Dairy products, especially eggs, have that type of demand. And to supply eggs, the supplier needs egg trays. That means egg tray making is a business where you can enjoy a consistent demand. But you will need an egg tray machine to start your business.

Why Start an Egg Tray Making Business?

Hardly anyone thinks about starting an egg tray making business. It’s a simple idea that often goes unnoticed. And you can turn it into an advantage. If there aren’t many people who think about this business, you will have an open market with little to no competitors.

You can become the primary supplier in your locality. For example, if the egg suppliers in your locality had to order egg trays from a supplier belonging to a different city or state, they would have to pay more because of transportation costs. Starting a business will mean the local egg suppliers won’t have to order from a different state. You can meet their demands and charge less than what they had to pay earlier. Take a view at this brand of machines https://bestonmachinery.com/egg-tray-manufacturing-machine/.

While investing in an eggs tray machine may seem expensive, it provides massive returns within a few years. Moreover, these machines come with an average of 20-year manufacturing warranty. You won’t have to spend on repairs anytime soon. Most importantly, an egg tray making business is still an affordable business proposition compared to some of the other ones that require more planning and money. When you find machines in China, many people recommend this machine https://bestonmachinery.com/egg-tray-making-machine/china/.

Requisites for Egg Tray Business

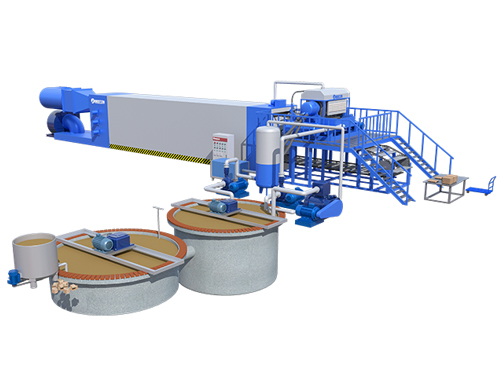

The first thing you will need is a warehouse or covered space to keep the machine. A fully automatic machine has all the parts assembled in two lines. The best part about a fully automatic machine is it also has a packing unit. This part stacks the egg trays and packs them properly. You don’t need to do anything alone. Let the machine do everything.

You need to know how many trays to pack in one set. This helps to reduce wastage. For example, you have an order of 1000 egg trays. You set the stacking machine to stack and pack two sets of 500 trays. Unfortunately, the pressure is so much that a few trays break in the middle while packing. Therefore, you should figure out the maximum number of trays the machine can packing without breaking anything.

Now that you know the crucial parts of starts an egg tray making business, calculate a budget, and invest wisely. Get the fully automatic egg tray machine.