When it comes to the tyre pyrolysis plant project reports, it’s important to understand what your needs are. There are multiple factors to account for and you will have to go through them one by one.

If you don’t do this, you are not going to appreciate the results that come along with a solution such as this. See this tyre pyrolysis plant project report.

Here is a look at what you are going to get with a tyre pyrolysis plant project reports and why it is valuable over the long haul.

Comprehensive Data

It is the data that a lot of people struggle with and that is what bothers time. You will want to understand what the market is like and what type of value you are going to get from pyrolysis oil plant manufacturers as soon as it is set up on-site.

With all of the information that is out there, it can become confusing to figure out what works and what does not.

This is why more and more business owners like the idea of getting a simple report that will shed light on what is needed.

Up-To-Date Information

You will want to take the time to look into everything and that includes the information you are going to get in front of you.

If you are not getting the information that you need, it can start to hold you back from prospering. Look into the value you will receive through the tyre pyrolysis plant project reports and know it is the real deal.

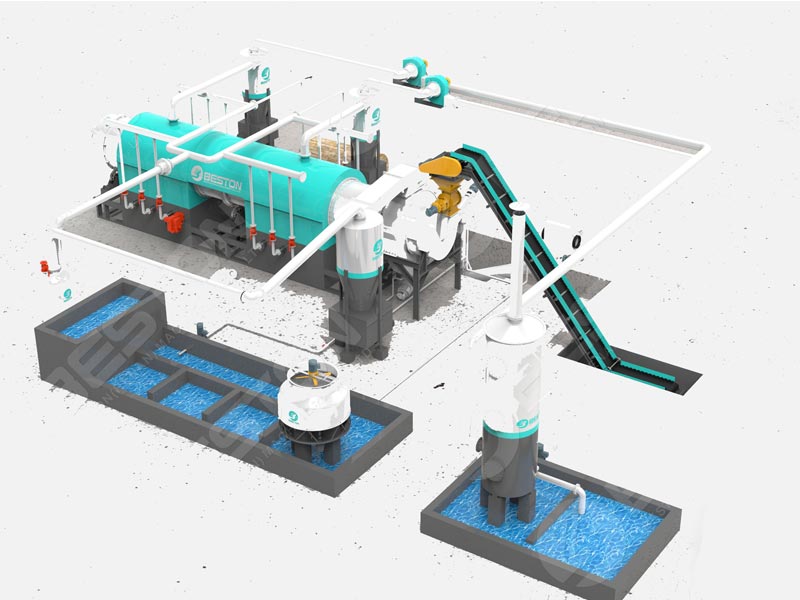

This is the type of information that will bring a smile to your face as it will be in line with what the market has to offer. This is information you can use right away and optimize your operation with. This pyrolysis machine in the Philippines is used to make oil from tyre, plastic and oil sludge.

Cutting-Edge Technology

It’s important to think about how the technology will improve what you are running on-site. A lot of business owners don’t get the time to dig through these details and that is what holds them back. If you take the time to go through this report, you will learn a lot about what works and what does not.

This is powerful information and it has a lot to do with the tech that is on offer. It is this tech that is going to be a game-changer and it will bring a smile to your face. You will know it is going to offer you with all of the details that are going to matter as time goes on.

The best tyre pyrolysis plant project reports is one that is going to shed light on what you need to know about having a plant that works. When you don’t have a good plant, it will not work as you want it to and that is what holds people back over time. When you need to crush the raw materials before pyrolysis, click https://bestonmachinery.com/tyre-shredder/ to find the suitable machine.

Keep things simple and make sure you are going with a plant that is in line with what is required for your business to prosper. Take the time to go through these details and ensure you are on the right path.