Do you have access to huge quantities of biomass? Are you searching for a way to productively use that biomass? How much do you know about the machines capable of producing high-quality charcoal from biomass(hornos metalicos para hacer carbon)? You will agree that charcoal is a high-quality fuel that is in huge demand. In addition to its use as a fuel, it is also widely used in a variety of industries for various purposes.

It has a huge demand in the pharmaceutical industry, food industry, and various other industries due to its many beneficial properties. Good quality charcoal can be produced from various materials such as bamboo, peanut shell, rice husk, sawdust, olive shells, and a variety of other materials. Producing charcoal from biomass is the best way to use waste biomass productively, especially when there is a huge demand for high-quality charcoal in your location.

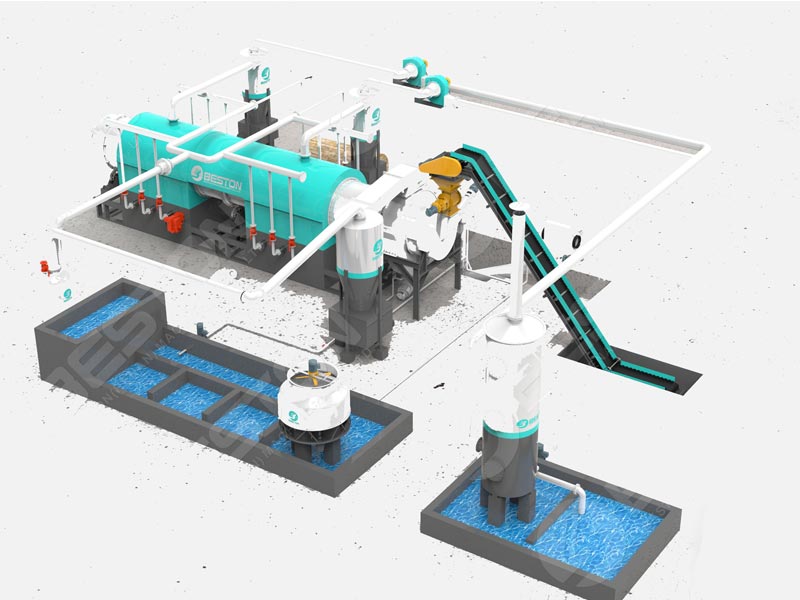

Producing a small quantity of charcoal from biomass isn’t that big a deal as it can be done manually. There are thousands of tutorials available online on how to do it manually. When it comes to producing high-quality charcoal at industrial levels, you would obviously need to invest in a good quality machine for processing. These machines are typically known as biomass carbonization machines(https://www.bestoneco.com/bst-50-planta-de-carbonizacion-enviado-a-cote-divoire/).

The first step in the process of converting biomass into charcoal is the elimination of moisture. In order to obtain good quality charcoal, it is recommended to keep the moisture levels under 10%. If the moisture level is higher, it will degrade the quality of charcoal and you wouldn’t be able to fetch a good price. The next step in the process is the carbonization itself. Once the carbonization(máquina de carbonización montado sobre patines) process has been completed, the next step involve purification and enrichment.

There are several advantages of investing in such a machine. The biggest advantage of such a machine is its high processing capacity. You can process a lot of biomass in one go which is something you cannot do manually. Another big advantage of investing in such a machine is the quality of charcoal produced by the machine.

No matter how good your manual charcoal-making technique is but it simply cannot compete with the quality of charcoal produced by a good quality machine. In fact, it would be wrong to call it a machine, as it is a plant consisting of a number of components. All these components are set to run in a particular order in order to produce the highest quality charcoal.

This machine(BESTON GROUP CO., LTD.) is much more energy-efficient as compared to manual processes. Also, these machines are sold in a variety of configurations including semi-automated operations and fully automated operations. A fully automated machine requires less labor which means you would save money on operational costs.

Overall, buying a machine capable of producing high-quality charcoal from biomass is a good investment. You should carefully check the manufacturer’s reputation before placing an order in order to ensure long-term success of your business. Make sure it is capable of generating producing high-quality charcoal at a low cost in order to remain competitive and win market share.