In the world of sustainable energy and resource management, pyrolysis oil is emerging as a quiet but powerful force. As we delve into the intricate web of its applications, we encounter a realm where waste is transformed into a valuable resource through the art and science of pyrolysis.

The Alchemy of Pyrolysis

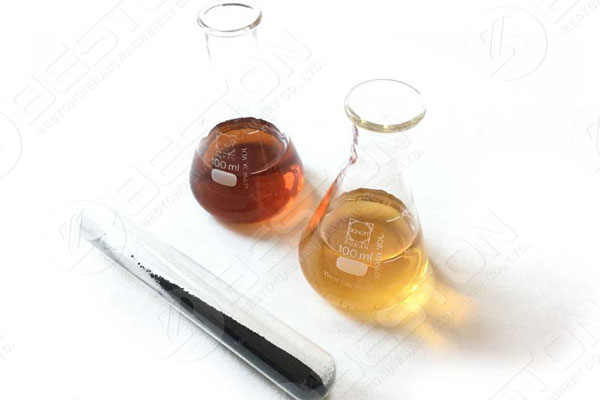

Pyrolysis, a process characterized by high-temperature decomposition of organic materials, yields a spectrum of valuable products. At the heart of this transformation lies pyrolysis equipment – the alchemist’s laboratory where waste undergoes a metamorphosis into treasure.

Fuelling the Future

- Power Generation

One of the most fascinating applications of pyrolysis oil is in power generation. When subjected to combustion, it releases energy in the form of heat, which can be harnessed to produce electricity. This makes it an ideal candidate for co-firing with coal or as a primary fuel source in power plants.

The versatility of pyrolysis oil in power generation doesn’t end there. Its cleaner combustion, lower greenhouse gas emissions, and potential for energy independence make it a contender in the renewable energy race.

- Industrial Furnaces

Industries have embraced the use of pyrolysis oil in their high-temperature processes. From smelting to kiln operations, the oil’s calorific value and lower sulfur content make it an eco-friendly choice, reducing both costs and environmental impact.

A Circular Economy Hero

- Waste Tyre Pyrolysis Plant

The menace of discarded tires finds a formidable adversary in the form of a waste tyre pyrolysis plant. These plants are designed to convert used tires into valuable products, including pyrolysis oil. Not only does this alleviate the problem of tire disposal, but it also contributes to the creation of a sustainable resource.

The pyrolysis oil from tires can be further refined into chemicals or used directly as a fuel source. This multi-pronged approach not only addresses waste concerns but also opens new avenues for resource recovery.

- Waste Plastic Pyrolysis Plant

In the battle against plastic pollution, waste plastic pyrolysis plant is an integral player. They take plastic waste, which would otherwise linger in landfills for centuries, and transform it into valuable pyrolysis oil. This oil can be utilized in a multitude of applications, thereby giving plastic waste a new lease on life.

Environmental Remediation

- Soil and Water Cleanup

Pyrolysis oil has demonstrated its prowess in environmental cleanup endeavors. Its sorptive properties are invaluable in the removal of contaminants from soil and water. The oil’s ability to absorb heavy metals and other toxins is a boon for land and water restoration projects.

- The World’s Carbon Ledger

By diverting organic waste from landfills and incineration, pyrolysis contributes to a significant reduction in carbon emissions. This, in turn, can generate carbon credits, aligning with global efforts to combat climate change. Industries and businesses embracing pyrolysis oil are not only reducing their carbon footprint but also creating financial incentives through carbon credit programs.

The Odyssey Continues

As research advances and innovation flourishes, the spectrum of pyrolysis oil applications continues to expand. From powering internal combustion engines to acting as a precursor for biofuels and chemicals, its journey is far from complete.

The Road Forward

In a world where sustainable practices are imperative, pyrolysis oil has emerged as a beacon of hope. Its capacity to transform waste into a valuable resource, coupled with its versatility in diverse applications, places it at the forefront of the circular economy.

At the nexus of technology and environmental stewardship, pyrolysis oil and its associated tyre/plastic to oil plant are exemplars of a future where waste is not discarded but embraced as an opportunity. The pyrolysis alchemy is not only redefining our approach to waste management but is also lighting the path towards a more sustainable and resourceful future.