Tyre waste is arguably one of the most serious problems facing the globe today. People everywhere are disposing of tyre bags, coffee cups, straws, bottles, and other tyre items without giving a second thought to what such waste is doing to the environment. The reality is that tyre takes a very long time to decompose, and many tyre items end up stuck inside the stomachs of some of the world’s largest sea creatures. Fortunately, the technology behind waste tyre pyrolysis plant has been advancing over the years with more investors now thinking about getting involved with the tyre waste problem.

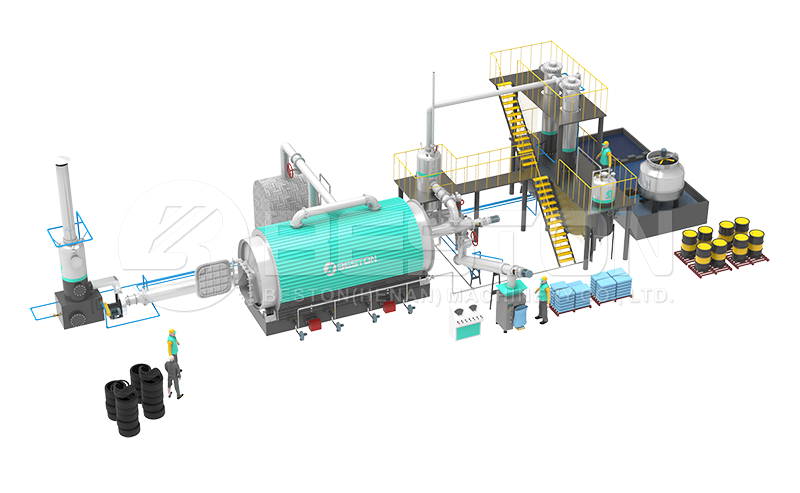

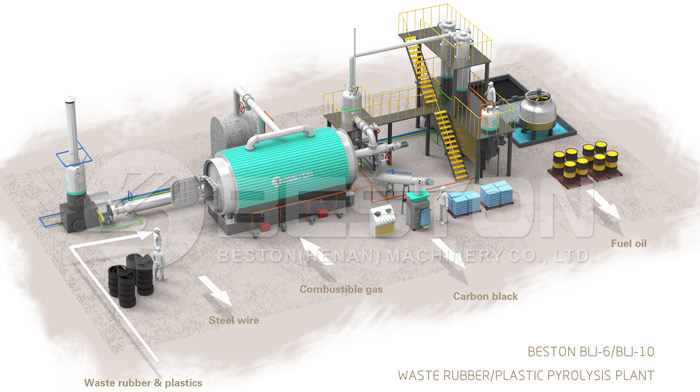

If you are thinking about building a tyre to fuel plant business, you may be pleased to learn that such a venture doesn’t require as large of an initial investment as many people think. All you need to do is purchase the machinery for a small pyrolysis plant and make sure you have plenty of tyre to keep it running. You should have no problems finding clients looking to purchase fuel from your plant on a long-term basis. Running such a plant is a great way to help the environment and create a profitable business. Click here to know more: https://bestonpyrolysisplant.com/continuous-waste-tyre-pyrolysis-plant/.

There can be many advantages to ordering a waste tyre recycling plant from suppliers in China. Manufacturers in China are able to produce top-quality equipment for a much lower cost than domestic manufacturers. The great thing about international trade is that you can get all the equipment you need to start a plant shipped from almost anywhere on the globe to your home country. While China is defiantly a top player in the tyre to fuel technology, many other overseas countries also sell plants to international customers. It would be a good idea to get price quotes from a range of different suppliers to ensure you are not paying over the odds.

The main challenge when it comes to buying a scrap tyre recycling plant is to ensure you avoid unreliable manufacturers and shady middlemen. It’s best to buy your plant directly from the factory where it will be manufactured. An online search for pyrolysis equipment manufacturers should help you to locate a few good sources. One of the best things about buying your machine directly from the manufactures is that it will be easy for you to source any spare parts you might need for future maintenance and repairs. What’s more, many manufacturers can provide you will detailed training on the operation of the machinery. Many people overlook the importance of such training when it comes to starting a new plant.