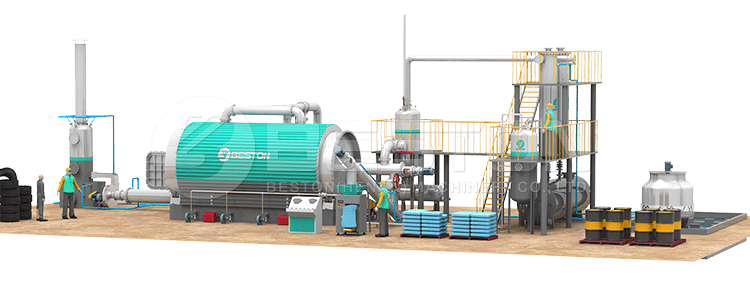

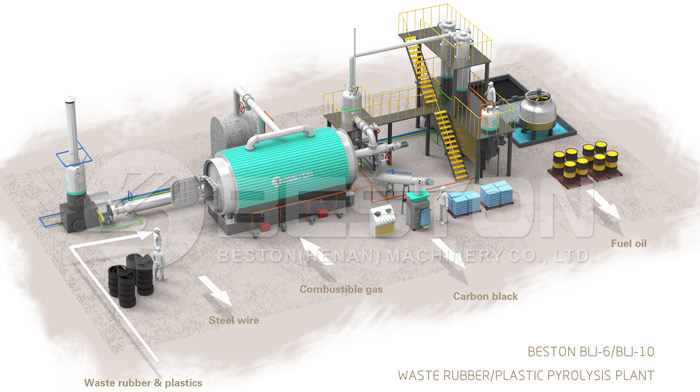

When you convert raw materials into burnable fuel, this is typically achieved with the pyrolysis machine. There are larger models, including pyrolysis plants, capable of producing tons of charcoal on a daily basis. If you just want to try this out, there are many companies that make them. You can find a tyre to oil plant cost online. The total cost will vary, especially when adding in the cost of taxes and shipping, but you can save money if you are diligent about your search.

Why Convert Tyres And Oil

If you do want to convert rubber tyres and oil, there are many reasons to do this. First of all, it can help you save money. Second, you will be able to start generating more revenue for your business. Finally, this will give you fuel that you can use with your own company. In most cases, the tyres that are in the ground, or the ones that you are receiving, are never going to be reprocessed. That’s what makes them so valuable. You will need a small scale pyrolysis unit to do this if you want to produce a sizable amount of oil.

Where To Find These Pyrolysis Plants

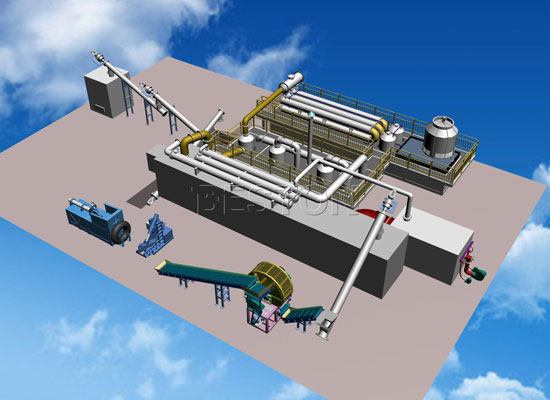

The best place to locate these machines and plans that can convert rubber tyres into oil is to search in countries that are known for producing phenomenal industrial equipment. Advertisements for what they are selling can be located within minutes when you are using the Internet. You will need to compare the specifications for all of the ones you are able to find. The specifications will include what the output is, the type of conversion that will occur, and how large each of these units actually is. You should also look at the amount of energy that is used to run these continually. These factors and figures can help you make a good decision.

How Large Should The Plant Be?

The size of the pyrolysis plant is simply dependent upon how much material you have to work with. For example, if you are working out a facility where there are millions of existing tyres, the largest unit will be the most ideal. If it is a location where you are receiving these on a daily basis, you might want to go for something a little bit smaller. If you have limited space, the smallest skid-mounted pyrolysis plant will likely suffice as it will allow you to convert as many as possible.

Obtaining a tyre to oil plant cost can be achieved by simply calling each manufacturer. They will be more than happy to share this information with you. Eventually, you will have plenty of information on which ones are the best, and you will know exactly how much you are going to spend. This will be a worthwhile investment for any company that has access to sizable amount of rubber tyres that can be converted to oil. After several years, you will see the value of owning one of these unique plants that can convert this material: https://www.bestongroup.com/tyre-to-fuel-recycling-plant/.