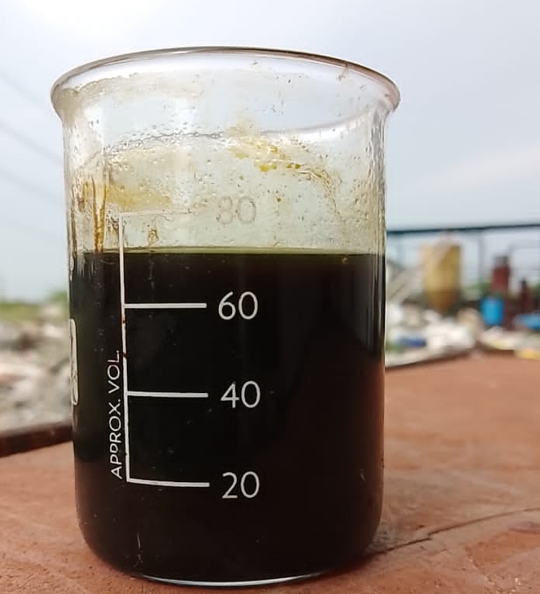

Oil sludge is a complex, hazardous waste material produced in large quantities in industries such as petrochemical, oil refining, and offshore drilling. Traditionally, this waste has been managed through methods like landfilling or incineration, both of which carry significant environmental and economic costs. However, the pyrolysis treatment of oil sludge offers an innovative, more sustainable solution that brings considerable economic benefits. By converting oil sludge into useful by-products like oil, gas, and solid residues, pyrolysis offers a closed-loop waste management system that is both economically viable and environmentally responsible.

Efficient Waste-to-Energy Conversion

One of the key economic advantages of oil sludge pyrolysis is its ability to convert waste into valuable resources. The oil sludge pyrolysis plant transforms the oil sludge into three main products: pyrolytic oil, syngas (synthetic gas), and solid char.

-

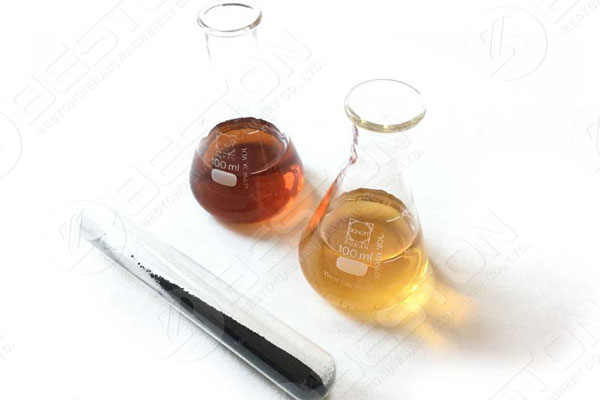

Pyrolytic Oil: The oil recovered from oil sludge pyrolysis can be used as a fuel substitute for power generation or as a feedstock for further refining into valuable chemicals or fuels. This creates a direct financial benefit by replacing more expensive, traditional energy sources. Additionally, the oil can be sold in secondary markets, providing additional revenue streams.

-

Syngas: The gaseous products, mainly composed of hydrogen, methane, and other hydrocarbons, can be captured and used as an energy source within the pyrolysis plant itself. This significantly reduces the plant’s external fuel consumption, lowering operational costs and improving overall energy efficiency. In some cases, the syngas can also be utilized to generate electricity, further enhancing the plant’s self-sufficiency and profitability.

-

Char: The solid residue, often in the form of carbon-rich char, can be used in various applications, such as activated carbon production, soil amendment, or even as a fuel in other industrial processes. The sale or reuse of char adds another economic advantage, reducing waste disposal costs while contributing to a circular economy.

Reduced Waste Disposal Costs

Oil sludge disposal has traditionally been costly, both financially and environmentally. Traditional methods such as landfilling require significant space, while incineration often results in high emissions and the need for complex air pollution control systems. Pyrolysis, on the other hand, offers a more efficient waste-to-value solution.

By diverting oil sludge from landfills or incineration, thermal desorption unit reduce the costs associated with waste disposal. In many cases, the revenue generated from the sale of by-products like pyrolytic oil and char can offset or exceed the operational costs of the pyrolysis plant, making the entire process economically self-sustaining.

Additionally, pyrolysis minimizes the environmental impact of waste management. The controlled, low-oxygen conditions in a pyrolysis plant ensure that harmful emissions, such as dioxins or furans, are minimized, which reduces the need for expensive emission control systems compared to incineration.

Cost Savings in Energy and Operational Efficiency

A significant economic benefit of oil sludge pyrolysis is the reduction in energy consumption. Traditional waste treatment methods such as incineration or chemical treatment often require substantial amounts of energy to process the sludge, which increases operating costs.

A pyrolysis plant, however, operates more efficiently. The syngas produced during the pyrolysis process can be used to power the plant’s operations, reducing the need for external energy sources. In many cases, the energy generated from the process is enough to meet the plant’s energy requirements, allowing the plant to operate at near-zero external energy costs.

Furthermore, the operation of a continuous pyrolysis plant, as opposed to batch-based processes, ensures higher throughput and more consistent production. This continuous feed system reduces the need for downtime, leading to more efficient and cost-effective operations.

Long-Term Financial Benefits and Return on Investment

The long-term financial benefits of oil sludge pyrolysis extend beyond immediate cost savings and revenue generation. By utilizing a pyrolysis plant to handle oil sludge waste, companies reduce their environmental liability and ensure compliance with increasingly stringent waste management regulations. This can help avoid penalties or fines associated with improper waste disposal.

In many cases, the initial capital investment in a pyrolysis plant can be recouped within a few years due to the savings in waste disposal costs, energy efficiency, and the sale of by-products. The relatively low operational costs, combined with multiple revenue streams, make the pyrolysis of oil sludge a financially attractive option for waste management.

Furthermore, the long-term environmental benefits of reducing landfilling and incineration create additional value. By adopting pyrolysis, companies can enhance their sustainability profile, potentially gaining favorable treatment from regulators, investors, and consumers who are increasingly focused on environmental responsibility.

Support for Circular Economy Initiatives

The pyrolysis treatment of oil sludge contributes to the circular economy by transforming waste into useful resources that can be reintegrated into the industrial value chain. The ability to recover energy and valuable materials from waste supports a more sustainable, closed-loop system that reduces dependence on virgin resources. Visit Beston Group to learn more about oil sludge recycling.

This aligns with global sustainability goals, which focus on reducing waste, promoting recycling, and minimizing the environmental footprint of industrial processes. By investing in a pyrolysis plant, companies not only gain economic advantages but also contribute to the broader goal of reducing global waste and conserving resources.