The production of lumber products is a common occurrence worldwide. People are always in need of boards for construction projects. At lumber mills, where these boards are produced, they create a substantial amount of waste products. This comes in the form of sawdust and trim ends. These can be recycled by the lumber mill itself. They may set up a cogeneration plant that can use them for fuel. However, you may want to consider bringing in a pyrolysis plant to produce additional products. Choose the right wood charcoal making machine manufacturers. There are many businesses that are excellent sources for wood charcoal manufacturing machines. Let’s first look at how you can find these businesses.

How To Locate Businesses That Produce This Type Of Machine

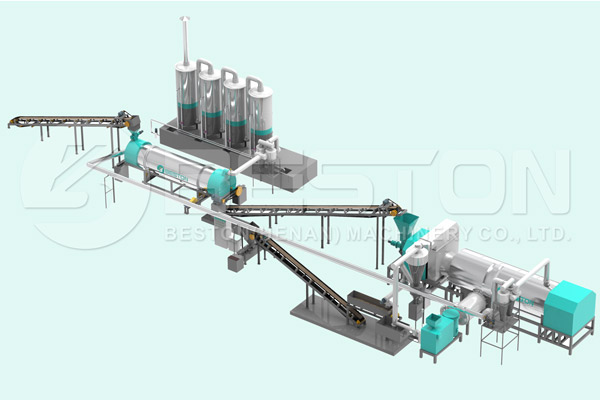

These machines are unique because they use pyrolysis technology. The materials will undergo a substantial conversion through the process of superheating the materials. Choose the right biochar machine for sale. There will be a complete absence of oxygen during this process. This is what prevents the combustion from happening. When this occurs, byproducts are made in the form of oil and charcoal. The fuel produced through this process can be sold as separate items that are in demand right now. These different products will be separated into areas. The liquid fuel will be stored in bins and the charcoal will be stored in containers.

How To Ensure This Business Venture Is Successful

This type of business can be successful when you have access to a constant source of wood-based materials. For example, if you process thousands of board feet every year, you will have tons of trim ends and sawdust to use. You may want to do a contract with a local lumber mill that is consistently harvesting this material. The key is to have access to large amounts of the material to be processed for the purchase of a pyrolysis plant to be justified. You can easily sell the charcoal, as well as the biofuel, to the highest bidder and make a profit. Besides, the waste wood pyrolysis plant is also a good option.

Where Can You Get Some Of The Best Machines?

The best machines tend to come from countries where they have been making pyrolysis plants for years. The technology that they are using these likely going to be more advanced than other locations. You may find reviews for different companies that make them. It is important to get estimates from as many companies as you can. This will enable you to see which wood charcoal making machine will offer you the best possibility of success: https://bestonasia.com/sawdust-charcoal-making-machine/.

The conversion of organic wood products into biofuel is very streamlined today. From small machines to large pyrolysis plants, people are doing this all over the world. The important thing is to choose reliable wood charcoal making machine manufacturers. If you have not used a pyrolysis machine before, they are very easy to learn. In just weeks, you should start to see the fruits of your labor by marketing the bio-oil and charcoal that will be produced. Always choose one of these machines based on how much wood you can get access to. Bestongroup helps you make the right decision. This will ensure your success in this industry of converting wood-based products into charcoal and fuel.