Bamboo charcoal production has emerged as a lucrative venture, primarily due to the growing demand for eco-friendly and sustainable products. With increasing awareness of environmental issues, bamboo charcoal has gained traction in various industries, including agriculture, construction, and energy. The profitability of bamboo charcoal production projects hinges on several factors, including the efficiency of the bamboo charcoal making machine, market dynamics, and operational costs. This article delves into the essential components of profit analysis for bamboo charcoal production projects.

Understanding Bamboo Charcoal Production

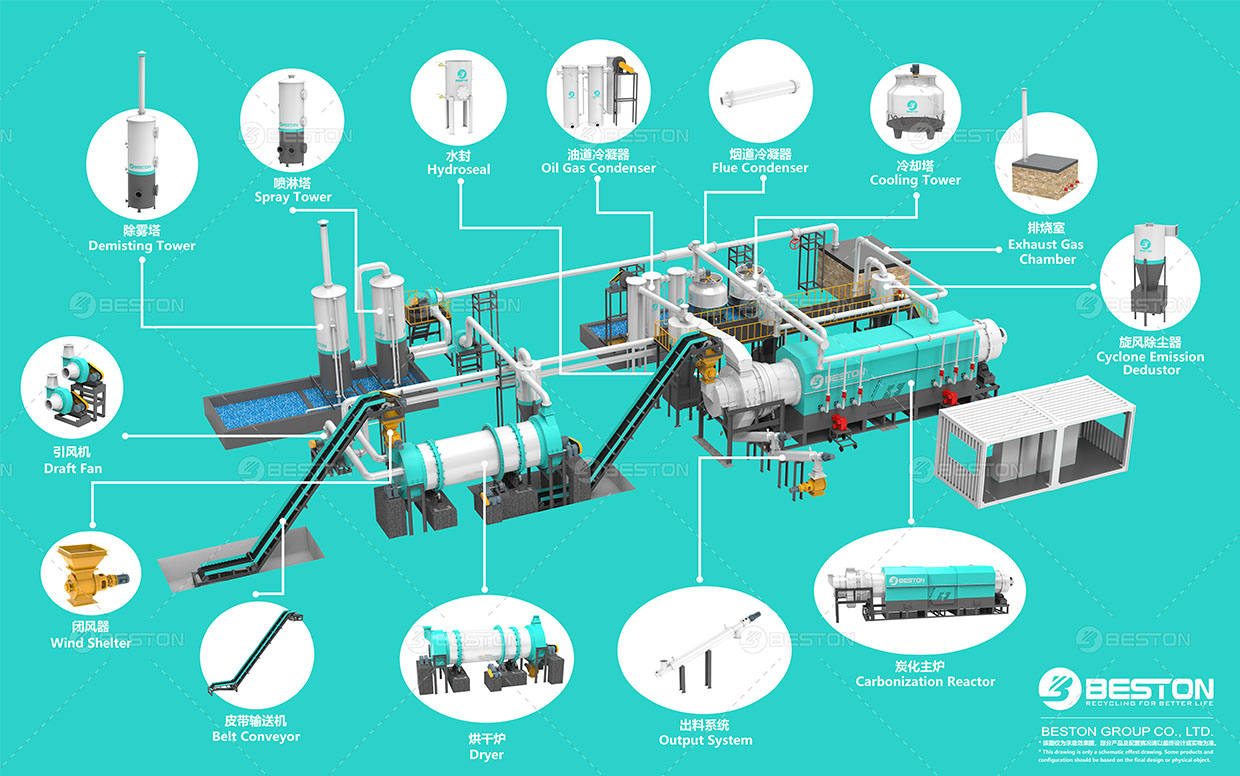

Bamboo charcoal is derived from the carbonization of bamboo at high temperatures, resulting in a highly porous and adsorbent material. The production process typically involves harvesting bamboo, drying it, and then subjecting it to carbonization using a bamboo charcoal making machine. This process not only creates a valuable product but also offers environmental benefits, such as waste reduction and carbon sequestration.

Market Demand for Bamboo Charcoal

The market for bamboo charcoal has expanded significantly in recent years. Several industries utilize bamboo charcoal due to its versatility and beneficial properties.

1. Agriculture

In agriculture, bamboo charcoal serves as a soil amendment, improving soil fertility and water retention. It enhances the microbial ecosystem, promoting healthier plant growth. With the organic farming movement gaining momentum, demand for bamboo charcoal in agriculture is poised for sustained growth.

2. Construction

The construction industry recognizes the advantages of bamboo charcoal in improving air quality and thermal insulation. Incorporating bamboo charcoal in building materials can enhance energy efficiency, appealing to eco-conscious consumers and developers alike.

3. Health and Wellness

Bamboo charcoal has found applications in health and wellness products, such as air purifiers and cosmetics. Its adsorbent properties make it effective in removing toxins and impurities, driving demand in the consumer market.

Cost Analysis of Bamboo Charcoal Production

A comprehensive cost analysis is crucial for determining the profitability of bamboo charcoal production projects. Key cost components include raw materials, equipment, labor, and operational expenses.

1. Raw Material Costs

Bamboo, the primary raw material, is abundant and renewable. The cost of sourcing bamboo varies depending on location and availability. Establishing relationships with local suppliers can minimize costs and ensure a steady supply. Additionally, utilizing waste bamboo from construction and landscaping projects can reduce raw material costs further.

2. Equipment Investment

Investing in a high-quality bamboo charcoal manufacturing machine is vital for optimizing production efficiency. The initial capital expenditure can be significant, but choosing a machine with advanced technology can lead to reduced operating costs and higher product yield. Key features to consider include automation, energy efficiency, and production capacity.

3. Labor Costs

Labor costs play a significant role in the overall production expenses. Efficient training programs can enhance workforce productivity. Additionally, implementing automation in the production process can minimize labor costs while ensuring consistent quality.

4. Operational Expenses

Operational expenses encompass utilities, maintenance, and logistics. Ensuring energy efficiency in the bamboo charcoal making machine can substantially reduce utility costs. Regular maintenance of the equipment is essential to avoid costly downtimes and extend the lifespan of the machinery.

Revenue Generation and Profit Margins

To assess the profitability of bamboo charcoal production projects, analyzing revenue streams and profit margins is essential.

1. Pricing Strategies

The pricing of bamboo charcoal products should reflect market demand and production costs. Conducting thorough market research can help determine competitive pricing. Premium pricing can be applied to specialty products, such as activated bamboo charcoal, which offers enhanced adsorption properties.

2. Diversification of Products

Expanding the product line can significantly enhance revenue generation. In addition to traditional bamboo charcoal, consider producing bamboo charcoal powder, briquettes, and activated bamboo charcoal. This diversification caters to various market segments and increases profit potential.

3. Volume and Scale

The scale of production directly impacts profitability. Larger production volumes typically lead to economies of scale, reducing per-unit costs. Implementing a continuous production process with the bamboo charcoal briquettes machine for sale can facilitate higher output and efficiency.

Financial Projections and Return on Investment (ROI)

To determine the feasibility of bamboo charcoal production projects, financial projections and ROI calculations are essential.

1. Break-Even Analysis

Conducting a break-even analysis can help identify the sales volume required to cover costs. This analysis considers fixed and variable costs, providing insights into the viability of the project.

2. ROI Calculation

Calculating the ROI involves comparing net profits to the initial investment. A positive ROI indicates a profitable venture. Factors such as production efficiency, market demand, and effective pricing strategies can influence the ROI significantly.

3. Long-Term Sustainability

Bamboo charcoal production aligns with sustainable practices, appealing to environmentally conscious consumers. By emphasizing the ecological benefits of bamboo charcoal, producers can enhance brand reputation and customer loyalty, contributing to long-term financial success.

Conclusion

Profit analysis of bamboo charcoal production projects highlights the critical factors influencing profitability, including market demand, cost management, and revenue generation. Investing in a high-quality bamboo charcoal making machine, optimizing operational efficiencies, and diversifying product offerings are essential strategies for maximizing profit potential. As the demand for sustainable products continues to rise, bamboo charcoal production presents an attractive opportunity for investors and entrepreneurs committed to environmental stewardship and economic viability. By conducting thorough financial analyses and maintaining flexibility in production strategies, stakeholders can capitalize on the burgeoning bamboo charcoal market, ensuring both profitability and sustainability. If you want to get more charcoal production solutions, please contact Beston company.