The paper egg tray is the end product produced by an egg tray making machine. They serve the purpose of protecting the delicate shells of the eggs during storage and transport. Most egg trays feature 30 holes. One of the advantages of the egg tray machine is the ability to change the molds in order to produce other products such as egg cartons or apple trays.

The typical raw materials that are used to make egg trays include old newspapers, craft paper, wood pulp, books along with any other type of recycled paper.

Types Of Egg Tray Making Machines

The egg tray making machines either come in manual versions which are able to produce 1000 to 1500 pieces, the semi-automatic machines which produced between 2000 to 4000 pieces, and the automatic machines which produce 4000 to 6000 pieces.

The Working Process Of The Egg Tray Making Machine

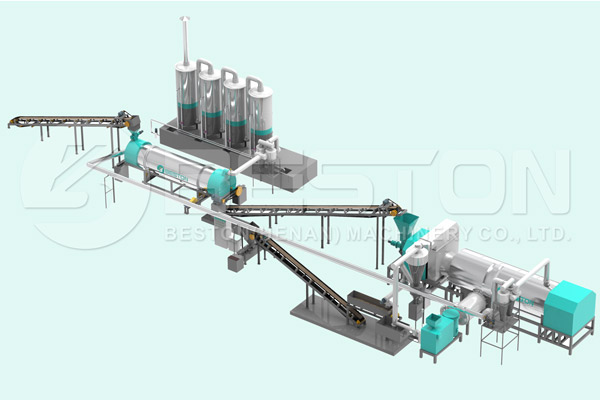

1. The Pulping Process

This process involves combining water with raw materials. This produces a slurry which is then dried to produce egg trays.

2. The Molding Process

This process involves the use of vacuum absorption and negative pressure which converts the slurry into the egg trays. These machines also have the ability to produce other items such as apple trays or egg cartons when you change the molds. Click here to know more: https://eggtraymakingmachine.net/egg-tray-making-machine-price/.

3. The Drying Process

Once the trays have been formed, the semi-finished and wet products are sent to a drying line. High-quality drying processes results in a reduction in the loss of trays that are poorly formed. The drying lines include either brick or metal.

With the use of a hot-press machine, it becomes possible to squeeze many trays together. From here the trays are easy to package. This step is also convenient for transporting the egg trays after the process of hot pressing.

The Advantages Of The Egg Tray Making Machine

• Low Operation Costs

The operations costs are kept to a minimum due to the low consumption of power and paper. In addition, the design of these machines recycles heat produced in the drying line which saves fuel.

• Easy Maintenance And Operation

If you choose the automatic egg tray making machine, this equipment is very easy to maintain and operate. In a typical situation, only 3 workers will be needed to operate one of the small models. This offers the opportunity to save money when it comes to labor input. This is the reason why the egg tray making machine has become a lucrative business opportunity for small-scale investors. Get egg tray machine price in India here.

• Eco-friendly

Recycling waste paper is extremely beneficial to the environment. It places less pressure on the landfills and is a cheap and environmentally friendly way to produce products such as egg trays or egg cartons. In addition, these pulp-molded trays are easy to dispose of and recycle once again.

The manufacturing industry for producing egg trays is highly profitable and promising. There are also reliable manufacturers that supply automatic, semi-automatic and manual egg tray making machines to choose from. These machines are suitable for both the small and large-scale investors. See this blog: http://bestonblog.blog.fc2blog.us/.