Biomass pyrolysis plants are plants that convert biomass into something known as biochar through a process of pyrolysis. Biomass is low-pollution, renewable, and offers extensive uses. The primary end product offers economic value along with wide applications. Many businesses use biomass pyrolysis plant to earn great profits. Biomass primarily refers to turning raw materials into charcoal.

Biomass pyrolysis processes involve the thermal decomposition of raw materials. This chemical reaction is a precursor of gasification and combustion processes that naturally occur within the first 2 seconds.

The common list of raw materials used in pyrolysis plants include:

– Wood from woodlands and natural forests

-Agricultural residues such as cane, coconut shells, green agricultural waste, coconut husks, rice straw, rice husks, straw, and more

– Sludge

What Can You Achieve With A Biomass Pyrolysis Plant?

Biomass pyrolysis plants also go by the name of biochar pyrolysis machines or biomass carbonization plants. They are mainly used for generating charcoal from a type of biomass waste using extremely high temperatures to heat the biomass. Click here to know more: https://bestonpyrolysisplant.com/.

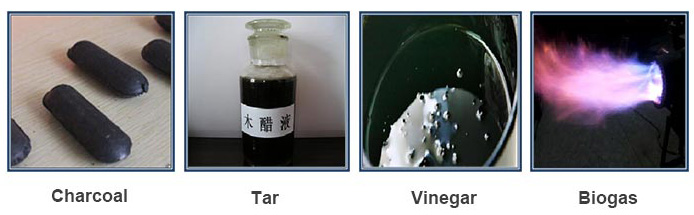

The charcoal produced from different types of biomass waste offers extensive applications across numerous industries. For the agricultural sector, biochar charcoal is frequently used as biological carbon fertilizers or as soil amendments to improve the condition of the soil and to facilitate harvesting. Biochar is also used as a type of fuel, a steel-coating agent, or activated carbon in many other sectors. Biomass is also converted into shisha charcoal or as a fuel for BBQs.

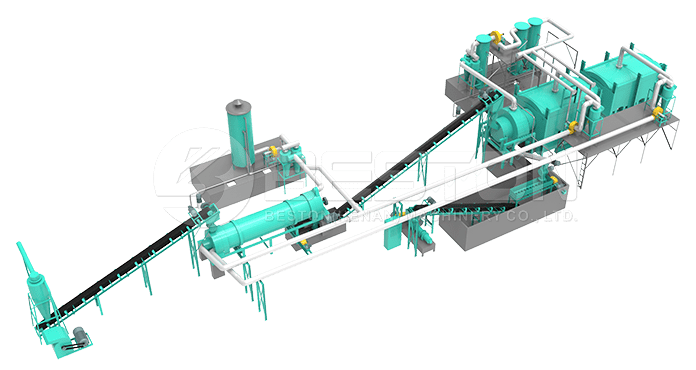

The biomass pyrolysis plants feature a double-layer design. This ensures that the low parts of these machines are in constant contact with heated air. This type of design facilitates raising the use of heat efficiency throughout the process.

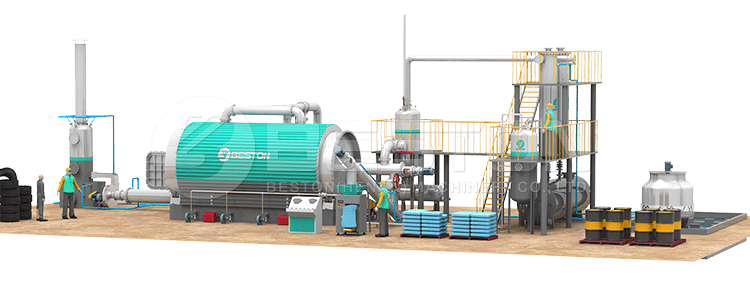

The desulfurization steam and smoke abatement are cooled by the condenser which ensures a pollution-free process that matches up to environmental protection standards.

In the process of production, very small amounts of combustible gas are produced. The gas that is produced is directed by a fan to provide a source of heat to the furnace of charcoal making machine. This process ensures an effective method to save energy.

The biomass pyrolysis plant only uses a single hot-air source for the entire process of these operations. This ensures a significant saving for customers that use these plants.

Biochar pyrolysis technology can decrease the volumes of combustible waste by as much as 95%.

Biomass pyrolysis plants adopt what is known as the 1 fire 2 step method, which is an innovative and unique technology when it comes to turning waste into a source of energy or fuel.

Other Applications Of The Pyrolysis Plants

The carbonization process of biomass is not only used for biomass waste but also to dispose of other types of waste. This includes oil sludge, medical waste, rubber, tires, and plastic. Through the process of high-temperature pyrolysis, these waste types are effectively changed into a type of fuel oil along with other valuable resources. These include steel wire and carbon black. The end products differ according to the raw materials. More information from the blog: http://bestonmachinery.mee.nu/.