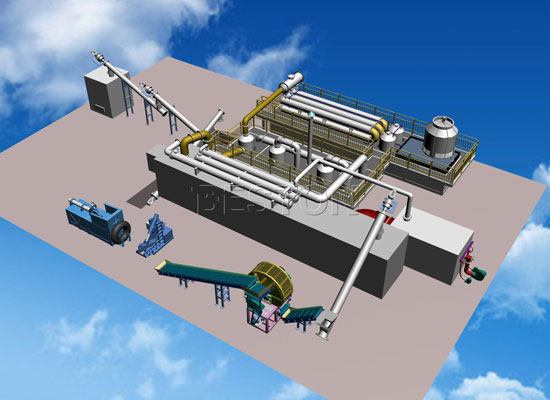

Continuous waste tire pyrolysis plant is set up around the world to cope the increasing quantities of global tire waste. Tire pyrolysis is an eco-friendly way to recycle scrap tires into usable commodities, such as fuel oil and carbon black. The need for eco-friendly tire recycling machines has never been greater. It is true that you can see the world’s largest tire landfill site in Kuwait from space. If you wanna get continuous pyrolysis plant price, why don’t contact Beston?

Continuous Waste Tire Pyrolysis Plant Core Components

1. Reactor

The reactor is perhaps the most important component in a fine waste tyre pyrolysis plant. There are two different types of reactors: rotary and fixed. The structure of the first type is such that the reactor can rotate 360-degrees to ensure all areas of the reactor are heated evenly. The rotary design helps to speed up pyrolysis and prolong the service life of the component. A fixed reactor has a stable design and does not rotate. Fixed reactors are used in fully continuous waste tire pyrolysis plants are they are more energy-efficient than reactors that utilize a batch working method.

2. Casing

A pyrolysis reactor is covered in a special casing that is designed to retain heat inside the main vessel and reduce fuel costs. It is also used for isolating oil-based cuttings.

3. Manifold

Vapor from the pyrolysis reactor moves into the manifold, which is designed to separate heavy and light oil. The light oil then rises to the next condensing systems while the heavy oil flows into a residual oil tank, Heavy oil containing fine dust is sent back into the reactor via an oil pump for further refinement.

4. Condenser

The condenser is used to convert the vaporized oil into liquid oil. The tubular design of condensers on top-rated continuous waste tire pyrolysis plant ensures that there is a large cooling area for condensing, which can significantly improve oil yield. What’s more, tubular water-cooled condensers are easy to maintain.

5. Dedusting System

The dedusting system is comprised of three layers of exhaust cleaning components to ensure there is no pollution in a plant’s emissions. The three layers including water washing, ceramic ring adsorption, and water spray. The de-dusting system is key to ensure that tire to oil machines meet strict environmental protection regulations.

There are batch, semi-continuous, and fully-continuous designs available. The type of plant design a buyer opts for will depend on the quantity of tires that need to process each week and space they have available for machinery in their facility. Budget restraints can also obviously affect the type of plant design available to tire recycling facility operators. Click https://BestonTurkey.com for the right model.