Pyrolysis is the process by which materials are decomposed using heat in an inert environment. It is an irreversible process that alters the chemical composition of materials leaving them enriched with carbon. The Beston tyre pyrolysis plant is a technologically advanced machine that incorporates green technology to produce oil from rubber, plastics, tyres, and waste products. The primary by-products that are produced by the machine are carbon black and pyrolysis oil, which can bring you great profits. That’s why tyre recycling machines South Africa is a very promising business.

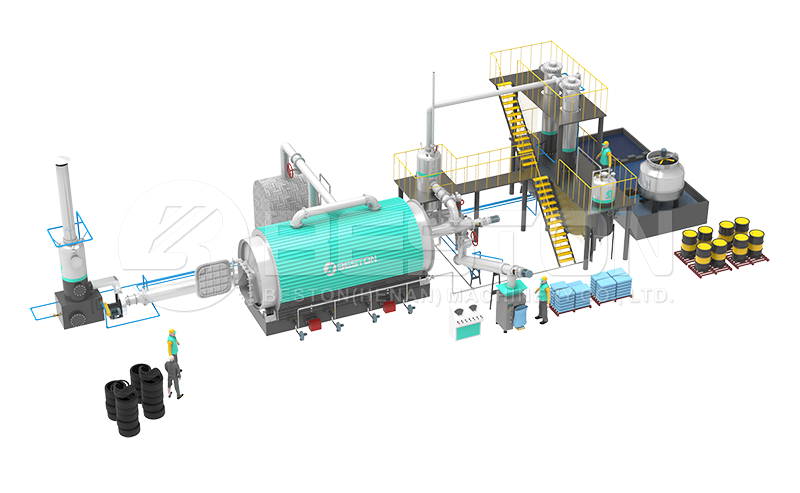

Components of A Tyre Pyrolysis Plant

1. Reactor- The reactor is the chamber in which the pyrolysis process occurs.

2.Condenser- The condenser is used to freeze the waste gases produced by the plant during operation.

3. Casing- The casing is an insulator which shields the pyrolysis plant against heat losses.

4. Manifold- The manifold sorts heavy and light particles before they are released into the condenser.

5. Oil Residue Tank- The tank is used to house the pyrolysis oil that comes out of the condenser.

6. Hydroseal- The hydro-seal is used to remove impurities and purify gases that are not flammable.

Cost Analysis of Pyrolysis Plant

Besides the uncountable benefits that come with the pyrolysis plant, it is essential to understand the factors that determine the cost of the plant. The factors include:

1. Nature of the Pyrolysis Process

The procedure employed by a particular pyrolysis plant will determine its cost. Pyrolysis plants that have capabilities to recycle more waste products cost more than those that can reuse a few waste products. A pyrolysis plant that can recycle tyres, plastics, and rubber.

2. Level of Technology

Pyrolysis plants which employ highly advanced technologies cost more than those that utilize simple technology. Advanced technology helps in minimizing the amounts of environmental pollutants that are released by the pyrolysis plants. Plants that can generate more green energy cost more because more capital is invested in developing and designing them.

3. Output Capacity

The processing output of the pyrolysis plant also affects its cost. Beston waste tyre pyrolysis plant can process 6 to 24 tons of raw materials each day.

4.Nature of the Reactor

Pyrolysis reactor is highly-automated and it costs most. The reactor is the heart of the pyrolysis plant, and it heavily determines the value of the plant.

End Products of Tyre Pyrolysis Plant

1. Fuel Oil- Used to process diesel for vehicles and can be sold as fuel.

2. Carbon Black- Used to make grinding and briquetting equipment.

3. Steel Wires- These are obtained from waste tyres and are used to make steel wires which can be sold directly.

Advantages of the Beston Tyre Pyrolysis Plant in South Africa

1. Subsidized Operation Cost- The tyre pyrolysis plant produces combustible gases that make the system self-sufficient. The exhaust gases produced during pyrolysis can be used to heat the reactor making the plant effective and efficient.

2. Convenient Operation and Maintenance- The tyre pyrolysis plant is highly automated and can be run by very few operators. Automation makes the plant more comfortable to operate than manual systems. All in all, Beston will help to reduce your waste recycling plant cost.

3. Creation of Employment- The pyrolysis plant creates employment for many people in South Africa. Workers are needed to load the tyres in the reactors, to maintain the plant in a clean state, and to monitor the various processes of the machine.

4. Effective Security Systems- The tyre pyrolysis plant from Beston is equipped with automated security such as pressure and temperature sensors which notify the operators of any potential dangers before they occur.

5. Minimization of Pollution- The plants are eco-friendly, and they help in conserving the environment.

Precautions When Working With Pyrolysis Plants

1. Workers should put on their safety gears to minimize injuries.

2. Only trained and qualified personnel should operate the plant.

3. Environmental friendly measures should be adopted to mitigate environmental pollution.

4. Regular maintenance activities should be done to the plant to maintain its performance efficiency.

5. Waste gases should not be released into the environment without proper treatment.

Pyrolysis plants are essential in mitigating environmental pollution and at the same time create sources of revenue. Therefore, the benefits of Beston tyre pyrolysis plant in South Africa cannot be underestimated. If you are interested, welcome to contact BESTON now!