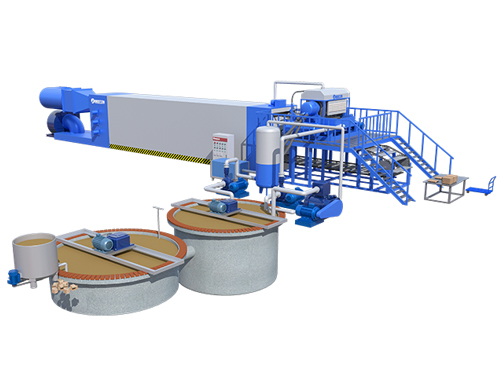

Paper pulp molding machines are used to create a variety of molded paper products, such as egg cartons, drink cups, and food packaging. The machine begins by mixing the paper pulp with water to form a slurry. The slurry is then poured into molds of the desired shape and left to harden. Once the molded product has hardened, it is removed from the mold and allowed to dry. Paper pulp molding machines are available in a variety of sizes and styles, making them suitable for use in a wide range of applications.

Benefits of using a paper pulp molding machine

Paper pulp molding machines have a number of advantages over traditional molding methods. Perhaps the most significant advantage is that paper tray forming machines can produce products with a much higher degree of precision. This is due to the fact that paper pulp can be formed into very specific shapes and then hardened into a mold. It allows for a much greater degree of control over the final product.

In addition, paper pulp molding machines are much faster than traditional molding methods, meaning that products can be produced in a shorter amount of time. These machines are also more environmentally friendly than traditional methods, as they do not use any harmful chemicals or require excessive amounts of energy to operate. Taken together, these advantages make paper pulp molding an attractive option for a wide range of applications: https://pulpmouldingmachines.com/small-egg-tray-making-machine/.

How to choose the right paper pulp molding machine

When it comes to paper pulp molding machines, there is no one-size-fits-all solution. The right machine for your business will depend on a number of factors, including the type of paper you want to produce, the volume of production, and the budget. Here are some key considerations to keep in mind when choosing a paper pulp molding machine for your business.

First and foremost, you need to decide what type of paper you want to produce. Paper industrial packing machines can be used to produce a variety of paper products, from disposable cups and plates to more durable items like shipping containers and construction panels. Once you have determined the type of paper you want to produce, you can narrow down your search to machines that are designed for that specific purpose.

Finally, you need to consider your budget when choosing a manual egg tray making machine. These machines can vary widely in price. You should set a realistic budget before beginning your search so that you can find a machine that fits within your price range.

Although there are many different types of paper pulp molding machines on the market, it is important to do your research before investing in a machine. Make sure you consider the size of your business, how much production you need, and what type of paper products you plan to produce.